What are the advantages and disadvantages of formwork?

Jun. 17, 2024

What are the advantages and disadvantages of formwork?

What are the advantages and disadvantages of formwork?

In the evolving landscape of construction, system formwork represents a significant leap forward in efficiency, precision, and safety. Unlike traditional formwork methods, which often involve bespoke solutions for each project, system formwork utilizes prefabricated, modular components designed for quick assembly and reuse. This article explores the primary objectives of system formwork and its impact on the construction industry.

Streamlining Construction Processes

The core objective of system formwork is to streamline the construction process. By using standardized, modular components, system formwork reduces the time and labor required for assembly and dismantling. This efficiency not only accelerates project timelines but also contributes to cost savings on labor and materials.

Enhancing Structural Integrity and Quality

System formwork is engineered to precise specifications, ensuring consistent quality and structural integrity in concrete construction. The uniformity of the components contributes to a higher quality finish, with fewer imperfections compared to traditional formwork. This precision is crucial for structural elements that must meet strict engineering standards.

Improving Safety on Construction Sites

Safety is a paramount concern in construction, and system formwork addresses this through its inherent design features. The modular nature of the system includes integrated safety components, such as guardrails and access platforms, reducing the risk of accidents. Additionally, the predictability and reliability of the assembly process further enhance on-site safety.

Facilitating Versatility and Adaptability

Despite its standardized approach, system formwork offers considerable versatility, accommodating a wide range of architectural designs and construction challenges. The modular components can be configured in various ways to suit different project requirements, from simple structures to complex architectural features. This adaptability makes system formwork a valuable tool for a diverse array of construction projects.

Promoting Sustainability in Construction

System formwork contributes to sustainability in construction through the reuse of formwork components across multiple projects. This reusability minimizes waste and reduces the demand for raw materials, aligning with environmental sustainability goals. Moreover, the efficiency of the system formwork process can lead to reduced energy consumption and lower carbon emissions on construction sites.

Objective Summary: System Formwork's Role in Modern Construction

The introduction of system formwork has revolutionized construction practices, offering a method that is efficient, safe, and environmentally friendly. Its objectives to streamline construction processes, enhance structural quality, improve safety, and promote sustainability demonstrate its value in modern construction. As the industry continues to evolve, system formwork remains at the forefront, driving innovation and excellence in building practices.

Advantages and Disadvantages of Plastic Building ...

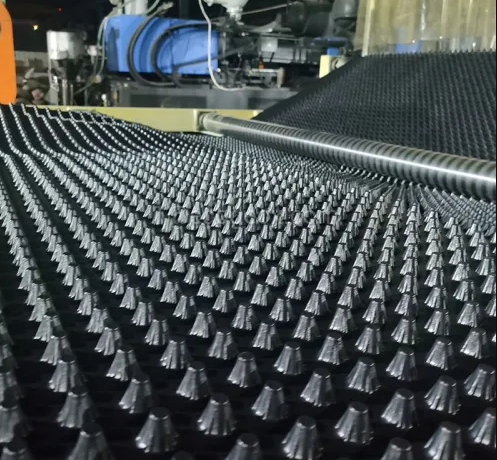

BOFU plastic formwork system

You will get efficient and thoughtful service from Zolo.

Related links:What are the advantages of polypropylene synthetic fiber?

Components and Structure of W Beam Guardrail

Essential Guide to Durable HDPE Pipe Floats

How does the Geotube technology work to contain and stabilize soil and other materials?

Thrie-Beam Highway Guardrail: Ensuring Road Safety

How to apply PU waterproofing glue on a concrete roof?

What are the advantages of aluminum sliding doors?

In the construction market, the selection and using of building formwork has always been the top priority of project quality and cost control. In recent years, plastic formwork has become more and more important in the construction market.

Plastic building formworks have certain advantages. Firstly, it has the characteristics of waterproof, corrosion resistance, acid resistance and alkali resistance, and are especially suitable for use in underground and humid environments. The plastic formwork has high strength, strong toughness, strong impact resistance, strong elasticity, and is not easy to be deformed, thereby greatly improving the reusable of the formworks.

Secondly, the plastic formwork has all specifications, light weight, light and easy to dismantle the mold, safe and reliable construction operation and handling, low labor intensity and high construction efficiency. The plastic formwork can be used together with various wood boards such as wood (bamboo) plywood.

After testing, the normal using of plastic formwork can reach more than 30 times, which can greatly reduce the construction cost, and the used formwork panels can be recycled, which is beneficial to the development of the formwork rental business. The plastic formwork does not need to be coated with a release agent during use, and is easy to clean by just water, therefore, the cleaning and maintenance costs of the forms are reduced. The surface of the plastic formwork is smooth, and it has good peeling property from concrete so is easy to demould. It can greatly speed up the construction progress, shorten the construction period and help to realize fair-faced concrete. In case of damage, the plastic formwork can recover, regenerate and reduce the pollution of waste to the environment.

Plastic building formworks also have certain disadvantages. It is a newer in the concrete forms industry, a powerful representative of the new building concrete formwork, but because it is a new form of building formwork, there are still some deficiencies compared to the steel building formwork and the wooden building formwork.

First, the static bending strength and static bending modulus of ordinary plastic building formworks are small compared with other formworks. The domestic applied plastic building formworks are lower in strength than bamboo (wood) one, and also lower than foreign ones such as GMT building formworks. The load-bearing of plastic building formwork is relatively low. The reason why it has a relatively low carrying capacity is because most of the plastic building formworks are mainly in the form of flat panels, which are mainly applied to the roof and floor slabs, , so just controlling the spacing between the secondary beams can meet the construction requirements. Therefore, if a plastic building formwork is to be applied to a wall column formwork, its strength must be high. The BOFU plastic building formwork is designed with a rib itself on the back of the formwork panels, which greatly enhances the strength of the formwork for wall formwork.

Second, the thermal expansion and contraction coefficient of ordinary plastic building formworks is larger than that of steel and wood, because plastic building formworks are greatly affected by temperature. The data shows that at high temperatures, the 3m long formwork can be stretched from 3mm to 4mm. If the construction is laid in the summer evening, the middle part of the formwork will be arched at noon. Therefore, BOFU plastic building formwork uses ABS plastic raw materials, which effectively reduces the coefficient of thermal expansion and contraction.

Building Concrete Forms

Thirdly, the electric welding slag is easy to burn the plastic building formwork. When the steel bar is connected, the welding slag temperature of the electric welding is very high, and it falls on the building formwork to easily burn the board surface, which affects the surface quality of the formed concrete. The high-performance raw materials of the BOFU plastic building form ensure that the surface of the formwork can withstand spot welding without affecting the formed concrete.

In summary, if you want to use plastic building formworks to reduce engineering costs and improve engineering quality, BOFU plastic modular formwork is a good choice.

BOFU plastic formwork system

For more information, please visit formwork prop.

How to Maintain and Extend the Lifespan of Your FRP Tank

The Difference Between Corrugated Metal Culvert and Plastic Corrugated Pipe

What is the advantage of steel roof truss?

What Types of Structures Benefit from Post-Tensioning?

Elevate Your Space: Masterful Tips for Decorating Marble Fireplace Surrounds

What’s the Difference: Paper and Fiberglass Mesh Drywall Tape

Are I-joists stronger than timber?

131

0

0

Related Articles

-

274

0

0

-

306

0

0

-

282

0

0

-

282

0

0

-

268

0

0

-

245

0

0

-

357

0

0

-

110

0

0

Comments

All Comments (0)