How To Maintain The Welding Positioner?

In recent years, welding positioners have developed rapidly in the construction machinery industry and have been widely used. Has quietly become indispensable machine equipment in the manufacturing industry. Today, the welding positioner manufacturer will explain the daily maintenance precautions of the welding positioner.

The routine maintenance of the welding positioner is divided into the maintenance of the welding chuck and maintenance of the welding positioner.

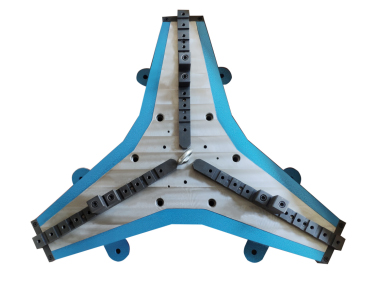

Maintenance of welding chuck

The welding chuck is an important part of the automatic welding positioner and requires frequent maintenance. When special circumstances occur, the frequency of welding maintenance must be increased. This can greatly extend the service life of the welding chuck and improve work and production efficiency. The correct maintenance method of welding chuck is as follows.

welding chuck

1. After checking, the main body of the welding chuck and the surface of the guide rail must be clean, air gun, and other tools to ensure that the welding chuck still has good accuracy after long-term use, so it is very important to regularly lubricate the welding chuck.

2. Apply molybdenum disulfide grease (black) at least once a day, and pour the grease into the nozzle of the welding chuck until the grease overflows the claw surface or the inner hole of the welding chuck (inner hole protective sleeve and connecting nut).

3. In order to prevent the internal rust of the welding chuck and reduce the clamping force, so that the workpiece cannot be clamped, it is better to use cutting oil with an anti-rust effect. Using cutting oil can prevent rusting inside the welding chuck.

4. After the operation is completed, an air gun or similar tool must be used to clean the welding chuck body and the surface of the slideway.

5. The welding chuck should be disassembled and cleaned at least once every 6 months to keep the sliding surface of the jaws clean and lubricated, so as to increase the service life of the welding chuck.

6. Check all parts for cracks and wear. The cast iron should be cut at least once every 2 months and cleaned thoroughly. If the damage is severe, replace them with new ones.

7. Different workpieces must adopt different clamping methods. If used to clamp irregular workpieces, the welding chuck will be damaged.

8. When the welding chuck pressure is abnormal, make the welding chuck under high pressure to clamp the workpiece, which will reduce the service life of the welding chuck. Therefore, when the gap of the welding chuck is found to be too large, a new welding chuck must be replaced immediately.

Related links:What Are the Grades of Lifting Chains?

Do whole house water filters remove limescale?

How to Choose the Right Telescopic Boom Lifting Height?

Top Trends in Automatic Wire Straightening: What You Need to Know for 2024

What is shaft forging?

How do I choose a hydraulic cylinder size?

Precision Air Conditioner: A Green Cooling Solution

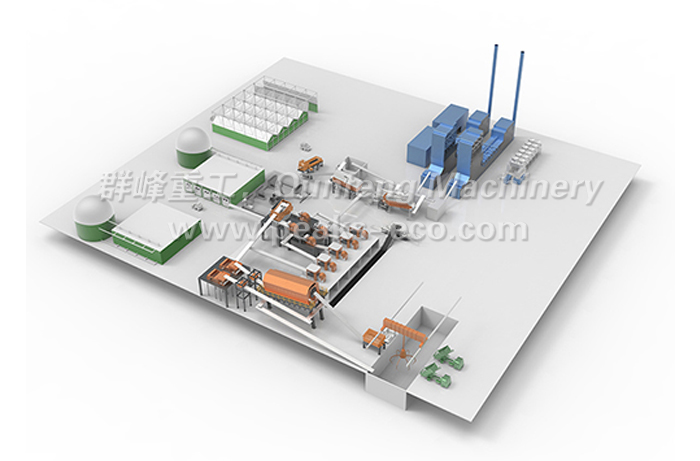

Maintenance of welding positioning machine

The welding positioner not only needs to maintain the chuck, but also the machine itself, otherwise, it will affect the accuracy and moving speed of the machine.

Welding positioner

1. After each electric welding is completed, the penetration on the workbench should be eliminated immediately and kept tidy.

2. Before using mechanical equipment, check the rotating transmission gears, rotating transmission gears, and their cables. If there is a waste on the rotating transmission gear, the rotating transmission gear should be eliminated immediately. If the skin is damaged, cracked, or poorly contacted, repair work should be carried out immediately. If repair is not possible, disassembly and replacement work should be carried out. In addition, the rotating transmission gears should be lubricated and filled with an appropriate amount of grease.

3. After the work is completed, various records should be filled in for future inspections.

4. Check the power distribution cabinet. If there is dust, wipe it clean immediately, and check whether the wiring terminal is firm, and tighten it immediately if it is loose.

5. Whether the rotating shaft and bearing of the workbench are normal, whether there is abnormal noise, if damaged, it should be replaced in time.

6. Check whether the remaining oil in the grease is sufficient and whether the oil quality is good.

In order to prolong the service life of the welding positioner, inspection, and maintenance work must be done at ordinary times, especially the maintenance work of the chuck. In addition, if there is a problem, it should be repaired in time to avoid affecting the use.

How do you know if a Barrel Plating Machine is good to buy?

Common Challenges in Semi-Automatic Lithium Battery Pack Assembly Lines

Which is Better for Clearing Land, an Excavator or a Bulldozer?

What is the difference between induction motor and slip ring motor?

Does cast iron make a good welding table?

How Does a Blow Molding Machine Work ?

Automated Screwdriving: The Pros and Cons

247

0

0

Related Articles

-

110

0

0

-

278

0

0

-

104

0

0

-

95

0

0

-

290

0

0

-

0

0

0

-

110

0

0

-

108

0

0

Comments

All Comments (0)