How Does a Multi-Head Weigher Calculate Combinations?

In the world of packaging, efficiency, and accuracy are paramount. Multi-head weighers have revolutionized the industry by enabling fast and precise weighing of various products. But have you ever wondered how these machines calculate combinations? In this article, we will delve into the inner workings of multi-head weighers and shed light on their remarkable ability to determine optimal weight combinations.

Understanding Multi-Head Weighers

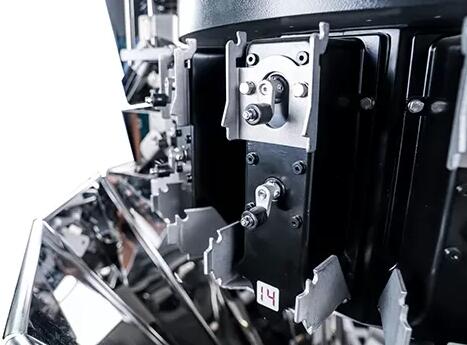

Multi-head weighers are sophisticated machines widely used in the packaging industry to accurately measure and distribute products. They consist of a centralized control system and multiple weighing heads, typically ranging from 8 to 24, depending on the model. Each weighing head contains a vibratory feeder and a weigh bucket. As the products pass through the feeders, they are distributed into the weigh buckets. The aim is to achieve the desired total weight by combining the appropriate number of products from different buckets.

Combination Calculation

The magic of multi-head weighers lies in their ability to calculate the optimal combinations of products to achieve the desired weight. The calculation process begins with the input of target weight and permissible error margins into the machine's control system. Based on this information, the weigher's software algorithm determines the optimal combination that comes closest to the target weight while adhering to the specified error limits.

The algorithm employed by multi-head weighers utilizes advanced statistical techniques and algorithms such as linear programming and dynamic programming. These algorithms analyze the weights of individual products and identify the combinations that minimize errors and maximize efficiency. The software adjusts and fine-tunes the combination calculation continuously, ensuring precise and consistent results.

Real-Time Adjustments

During operation, multi-head weighers constantly monitor the weight of products in the buckets. If the system detects a deviation from the target weight, it makes real-time adjustments to achieve accurate results. These adjustments involve altering the number of products dispensed from each bucket to maintain the desired weight combination. By employing rapid feedback loops and sophisticated control mechanisms, multi-head weighers ensure that the calculated combinations remain accurate, even in dynamic packaging environments where product characteristics can vary.

Conclusion

Multi-head weighers are a testament to the remarkable advancements in precision weighing technology. Through sophisticated algorithms and real-time adjustments, these machines calculate combinations that achieve optimal weights with high accuracy. By incorporating multi-head weighers into packaging processes, businesses can streamline their operations and deliver products efficiently while minimizing waste and maximizing customer satisfaction. We are a multi-head weigher supplier. If you are interested in our products, please contact us now!

335

0

0

Comments

All Comments (0)