Hairline Finish Stainless Steels

May. 13, 2024

Hairline Finish Stainless Steels

What is hairline finish?

If you are looking for more details, kindly visit hairline surface finish.

Hairline was the surface with endless brushing lines extend uniformly along with the length of coil or sheet. Hairline brushed finish's a well-defined directional finish with long and fine line which is also called HL, Long-Grain finish or Long-Grit finish. It's widely used in elevator panels, lift cabins and entrance, escalators, automotive sector, interior cladding, building facades and other architectural applications.

AVAILABLE SIZES

GradeTypeThickness75091410001219125015001524 304/304L COIL/SHEET 0.4~3.0 ● ○ ● ● ● ● ● 316L COIL/SHEET 0.5~3.0 ● ○ ○ ● ● ● ● 430 COIL/SHEET 0.4~3.0 ● ○ ● ● ● ● ● 441 COIL/SHEET 0.4~3.0 ○ ○ ○ ○ ○ ○ ○- Regular coils are typically supplied with an inner diameter of 508 / 610mm

- Special dimensions was accepted on request

- Customized specific strip are acceptable

- Customized specific cut-to-length are acceptable

- PE/Laser PE/Optic Fiber Laser PE are available on request

How To Make Hairline Finish Stainless Steel

What’s Hairline Finish In Stainless Steel?

In stainless steel, “Hairline Finish” is a surface treatment that gives the stainless steel surface a fine texture similar to hair, making it look smooth and delicate. This treatment method is usually used to improve the appearance, texture and decoration of stainless steel products, making them more modern and high-end.

Characteristics of a hair finish include subtle horizontal or vertical textures that look like tiny hair strands. The purpose of this treatment is to adjust the texture of the stainless steel surface to make it more uniform and detailed, and to produce a reflective effect at a certain angle, thereby presenting a unique appearance.

This surface treatment is usually achieved by mechanical grinding, polishing and other processing methods. Different manufacturers and processes may use slightly different methods, but the overall goal is to create a stainless steel surface with a specific texture and shine.

How Do You Make Stainless Steel Matte?

To achieve a matte finish on stainless steel, you can follow these general steps:

-

Surface Preparation:

Begin by cleaning the stainless steel surface thoroughly to remove any dirt, grease, or contaminants.

Sand the surface with a coarse abrasive material to create a uniform and slightly rough texture. This helps the matte finish adhere better.

-

Grinding:

Use a grinding wheel or belt grinder with a coarse grit to grind the stainless steel surface. This process helps to remove any imperfections and create a consistent matte appearance.

-

Fine Sanding:

After grinding, use progressively finer grits of sandpaper to further refine the surface. This step contributes to achieving a smoother matte finish.

-

Chemical Treatment (Optional):

Some processes involve the use of chemical treatments to achieve a matte finish. For example, a chemical etching solution or pickling paste can be applied to the stainless steel to create a matte appearance. However, use caution and follow safety guidelines when working with chemicals.

-

Media Blasting (Optional):

Another method to achieve a matte finish involves media blasting using abrasive materials like glass beads or aluminum oxide. This process can help remove any remaining imperfections and create a uniform matte surface.

-

Passivation (Optional):

Consider passivating the stainless steel to enhance its corrosion resistance. Passivation involves the removal of free iron and other contaminants from the surface.

-

Final Cleaning:

After achieving the desired matte finish, thoroughly clean the stainless steel to remove any residues from the surface treatment processes.

It’s important to note that the specific methods and tools used may vary based on the desired level of matte finish, the equipment available, and the expertise of the operator. Additionally, safety precautions should be taken, especially when working with abrasive materials or chemicals.

What’s The Stylish Way To Finish Stainless Steel?

The stylish finishing of stainless steel often depends on the specific aesthetic preferences and design trends. However, a few popular and stylish finishes for stainless steel include:

-

Mirror Finish:

Achieving a highly reflective mirror finish involves polishing the stainless steel surface to a smooth and shiny appearance. This finish is sleek, modern, and adds a touch of sophistication to products and surfaces.

-

Brushed Finish:

The brushed finish involves creating fine parallel lines on the stainless steel surface, giving it a textured and elegant look. It is often used in appliances, kitchen fixtures, and architectural elements.

-

Hairline Finish:

As mentioned earlier, the hairline finish features fine, subtle lines on the stainless steel surface, resembling the texture of hair. This finish is contemporary and is commonly used in decorative applications.

Related links:

25 Must-Have Kitchen Features to Add Storage and Style

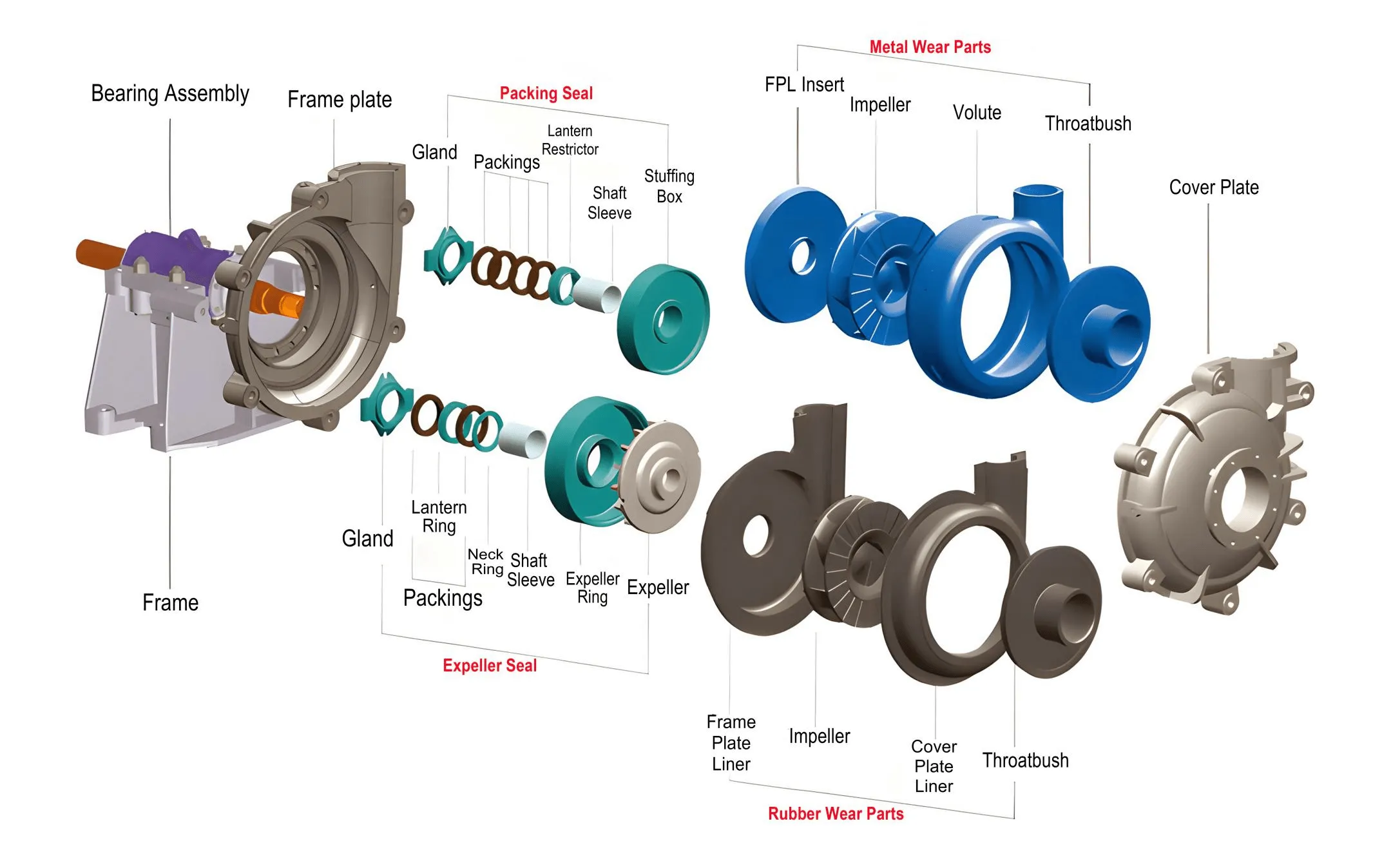

How Does a Gravel Pump Work?

What is bellow seal globe valve?

Vertical Slurry Pump vs Horizontal Slurry Pump: Making the Right Choice

What are the benefits of Flat Wire Compression Springs?

Can Plastic Be CNC Machined?

What are the application fuilds of rapid prototyping process?If you want to learn more, please visit our website stainless steel decorative divider.

-

PVD Coating:

Physical Vapor Deposition (PVD) coating involves applying a thin film of a durable and decorative material onto the stainless steel surface. This can result in a variety of stylish colors and textures, enhancing both aesthetics and durability.

-

Antique Finish:

Creating an antique or distressed finish on stainless steel involves processes like distressing, patination, or using special coatings to give the metal an aged or vintage appearance. This finish can be particularly appealing in certain design themes.

-

Custom Patterns or Etching:

Adding custom patterns or etching to the stainless steel surface can create a unique and stylish look. Intricate designs or branding elements can be etched onto the metal, providing a personalized touch.

-

Powder Coating:

Applying a powder coating to stainless steel allows for a wide range of color options and finishes. This method not only adds style but also provides an additional layer of protection against corrosion.

-

Matte Finish:

A matte finish is achieved by sanding or brushing the stainless steel surface to create a non-reflective, subdued appearance. It is a modern and trendy choice for various applications.

Ultimately, the choice of a stylish finish depends on the overall design concept, the intended use of the stainless steel, and personal preferences. Combining different finishing techniques or incorporating innovative design elements can result in a truly unique and stylish stainless steel product or surface.

What’s The Difference Between Hairline And 2B Finish?

Hairline finish and 2B finish are two distinct surface finishes applied to stainless steel, and they differ in terms of appearance and processing.

Hairline Finish:

Appearance: The hairline finish, also known as a satin finish or No. 4 finish, is characterized by fine lines or scratches on the stainless steel surface. These lines are typically oriented in one direction, creating a subtle and elegant appearance reminiscent of fine hairlines.

Processing:: Hairline finish is achieved through processes such as grinding, polishing, or brushing. Mechanical abrasion is used to create the fine lines on the surface, giving it a smooth and decorative texture.

Applications:Hairline finish is commonly used in decorative applications, such as architectural elements, furniture, and appliances, where an aesthetically pleasing appearance is desired.

2B Finish:

Appearance: The 2B finish is a more standard and smooth finish compared to hairline. It has a semi-reflective, moderately shiny appearance with a slight cloudiness. It lacks the fine lines or patterns found in a hairline finish.

Processing: The 2B finish is achieved through a cold-rolling and annealing process. The stainless steel is cold-rolled to a specified thickness and then annealed in a controlled atmosphere to remove any scale formed during the rolling process.

Applications: 2B finish is widely used in industrial applications where a smooth, corrosion-resistant surface is needed. It is common in equipment such as tanks, pipes, and kitchen appliances.

In summary, the main differences between hairline and 2B finishes are in their appearance and processing methods. Hairline finish is more decorative with fine lines, while 2B finish is smoother and more standard, suitable for a variety of industrial applications. The choice between the two finishes depends on the intended use, aesthetic preferences, and the desired level of surface smoothness.

How To Make Hairline Finish Stainless Steel

To sum up, you can probably understand the process of making stainless steel hair surface. The following are the steps required to make stainless steel hair surface for reference:

Grinding: Use a grinder or grinding wheel to grind the surface of stainless steel to remove the rough parts of the surface. Select the appropriate grinding tool and particle size to ensure a uniform surface.

Polishing: Using polishing tools, such as a polishing machine or polishing cloth, to further polish the ground surface. Polishing materials of different particle sizes can be used to gradually increase the gloss.

Corrosion treatment (Passivation): Pickling or other corrosion treatments are performed to remove oxides and other impurities on the surface. This helps improve the corrosion resistance of stainless steel and makes the surface smoother.

Electropolishing: This is a method of electrochemical polishing of stainless steel in an electrolyte solution. It can further improve the surface finish and improve the appearance of stainless steel.

Cleaning: After completing the above steps, clean the stainless steel surface thoroughly to remove any remaining corrosion or polishing agents

Post time: Dec-08-2023Want more information on rose gold sheet metal? Feel free to contact us.

What is precision surface finishing?

Why are ball bearings so important?

Isuzu Engine: The Ultimate Powerhouse for Your Vehicle

What is a Double Eccentric Butterfly Valve used for?

Pros And Cons Of Thermoset Injection Molding

What are Radiant Tubes?

Selecting the Right Belleville Washer for Your Application: Factors to Consider

137

0

0

Related Articles

-

255

0

0

-

223

0

0

-

263

0

0

-

286

0

0

-

294

0

0

-

293

0

0

-

280

0

0

-

243

0

0

Comments

All Comments (0)