The Ultimate Guide to High-Quality Tube Shoulder Injection Moulding Machines

Jun. 29, 2024

If you're in the market for high-quality tube shoulder injection moulding machines, you've come to the right place! In this ultimate guide, we'll walk you through everything you need to know about these machines so you can make an informed decision. Let's get started!

1. Understanding Tube Shoulder Injection Moulding Machines.

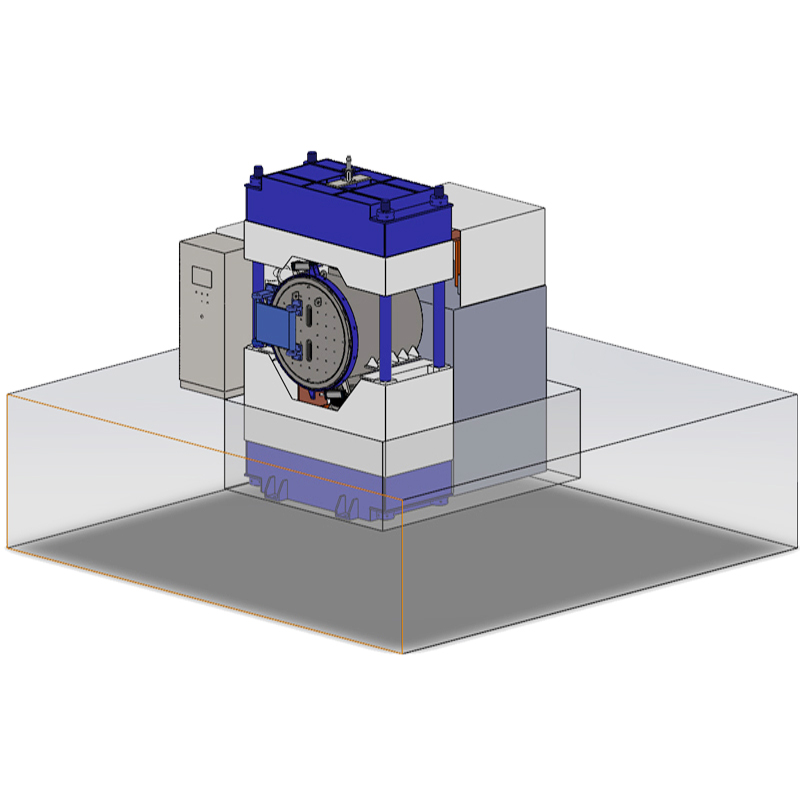

Tube shoulder injection moulding machines are used to create plastic tubes with shoulder seams. These machines use injection moulding technology to produce high-quality tubes with precision and efficiency.

2. Features to Look For.

When shopping for a tube shoulder injection moulding machine, look for features such as high-speed production capabilities, a robust clamping system, and advanced control systems for precise operation.

3. Choosing the Right Supplier.

It's essential to choose a reputable supplier when purchasing a tube shoulder injection moulding machine. Look for a supplier with a track record of delivering high-quality machines and excellent customer service.

Related links:Unveiling Precision Engineering: The 6-Axis 8-Module CNC Gear Hobbing Machine

What is an anodizer machine?

Efficiency Unveiled: How Vacuum CVD Systems Revolutionize Coating Applications

How much does a fiber laser cutting machine cost?

Unveiling the Secrets of PDC Drill Bits: Powering the Modern Age of Drilling

Blow Molding Machine Buying Guide

How do you package powder products?

4. Maintenance and Support.

Regular maintenance is crucial to keep your machine running smoothly. Make sure to follow the manufacturer's guidelines for maintenance and seek support from your supplier if needed.

5. Contact Us for More Information.

If you have any questions or need assistance with choosing the right tube shoulder injection moulding machine for your needs, don't hesitate to contact us. Our team is here to help you make the best decision for your business.

In conclusion, high-quality tube shoulder injection moulding machines are essential for producing plastic tubes with shoulder seams. By understanding the features to look for, choosing the right supplier, and prioritizing maintenance and support, you can ensure that your machine operates efficiently and produces top-quality tubes. If you're ready to invest in a tube shoulder injection moulding machine, contact us today to learn more about our products and services.

For more high quality tube shoulder injection moulding making machine, injection mould for bmc china, high quality disposable twist lancets making machineinformation, please contact us. We will provide professional answers.

Related links:How to Build a 3D Welding Table

What are the advantages of using Gang Type CNC Lathe?

The Inner Workings of a Production Freeze Dryer

Harnessing the Power of Ozone Generators: A Deep Dive into Applications and Benefits

Is it worth buying a new gas boiler?

What is the temperature of a vibrating screen bearing?

Everything You Need to Know About Pipeline Welding

144

0

0

Related Articles

-

254

0

0

-

483

0

0

-

299

0

0

-

287

0

0

-

330

0

0

-

265

0

0

-

309

0

0

-

377

0

0

Comments

All Comments (0)