Revolutionizing the industry: 3D printing pump actuators - Why are manual manufacturing methods becoming obsolete?

Jun. 07, 2024

Goto hankun to know more.

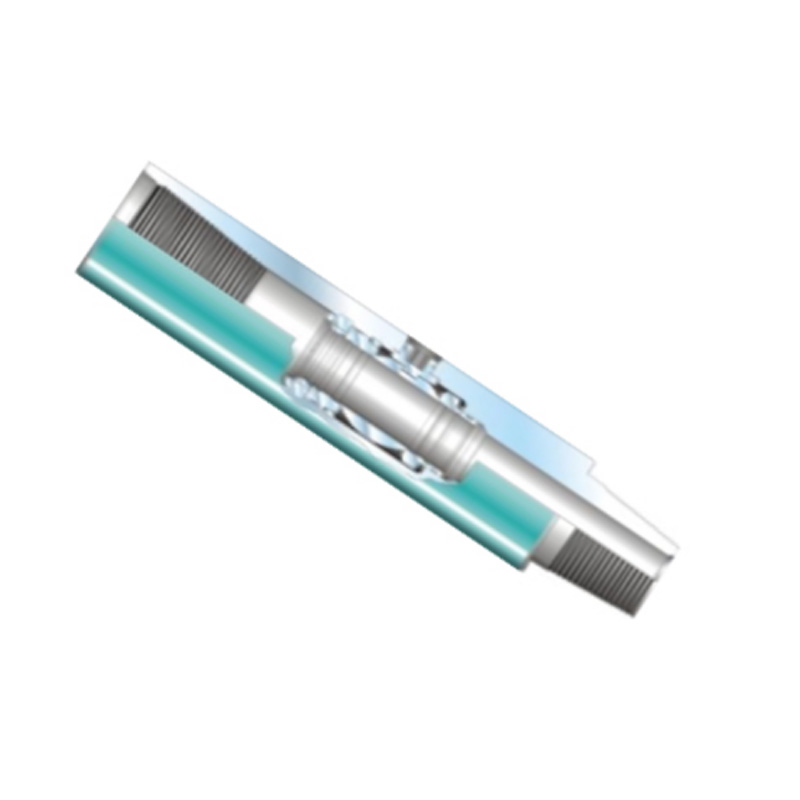

Manual manufacturing methods are quickly becoming obsolete in the pump actuator industry, thanks to the revolutionary technology of 3D printing. In this article, we will explore why 3D printing is transforming the way pump actuators are produced and why manual methods are no longer sufficient.

### Advantages of 3D Printing.

1. **Speed**: One of the main reasons why manual manufacturing methods are becoming obsolete is the speed at which 3D printing can produce pump actuators. Traditional methods require labor-intensive processes that can take days or even weeks to complete. With 3D printing, a pump actuator can be produced in a matter of hours.

.

2. **Precision**: 3D printing allows for extremely precise and accurate production of pump actuators. Manual methods often result in human error, leading to inconsistencies in the final product. 3D printing ensures that each pump actuator is made to exact specifications every time.

## Cost-Effectiveness.

1. **Material Usage**: Manual manufacturing methods often result in a large amount of waste material, driving up costs. 3D printing is much more efficient in terms of material usage, minimizing waste and reducing overall production costs.

.

Related links:4 Tips to Choose the Right Disc Lock Washers

4 Tips to Choose the Perfect Spring Wave

Forklift Paper Roll Clamp vs. Standard Clamp: Key Differences

Longhe Attachment OEM vs. Alternatives: Which is Right for You?

How Longhe Attachment Solutions Enhance Your Productivity?

ISO Standards for Fasteners: Explained

Why is Flanged Ball Valve Better?

2. **Labor Costs**: Manual labor is costly and can be prone to errors. 3D printing requires minimal human intervention, which helps reduce labor costs significantly.

## Innovation and Customization.

1. **Design Flexibility**: 3D printing allows for a level of design flexibility that is not possible with manual methods. Pump actuators can be customized to meet specific requirements, leading to more innovative solutions.

.

2. **Rapid Prototyping**: With 3D printing, companies can quickly prototype new pump actuator designs and test them before full-scale production. This allows for faster innovation and adaptation to changing market demands.

## Conclusion.

The pump actuator industry is being revolutionized by 3D printing technology, making manual manufacturing methods obsolete. The speed, precision, cost-effectiveness, and innovation offered by 3D printing are driving companies to adopt this cutting-edge technology. As the industry continues to evolve, 3D printing will play a crucial role in shaping the future of pump actuator production.

Please visit our website for more information on this topic.

Contact us to discuss your requirements of pump actuator manufacturing. Our experienced sales team can help you identify the options that best suit your needs.

Related links:Key Considerations to Keep in Mind When Selecting Custom Mining Straight Bevel Gears

4 Advice to Choose a Long-Lasting Attachments

How Can Mining Bevel Gear Exports Innovate?

4 Tips to Select the Right Longhe Attachments OEM

4 Tips to Select the Perfect Kibble for Your Dog

How Does Concrete Kibble Improve Outdoor Spaces?

What is Longhe Attachment ODM and Why?

157

0

0

Related Articles

-

140

0

0

-

135

0

0

-

133

0

0

-

127

0

0

-

204

0

0

-

375

0

0

-

327

0

0

-

411

0

0

Comments

All Comments (0)