How to Install Flexible Metal Conduit?

Mar. 04, 2024

Flexible Metal Conduit (FMC) installation is a critical aspect of electrical wiring projects. It ensures safety, durability, and efficiency in electrical systems. In this comprehensive guide, we'll walk you through the step-by-step process of installing flexible metal conduit, covering everything from preparation to final inspection.

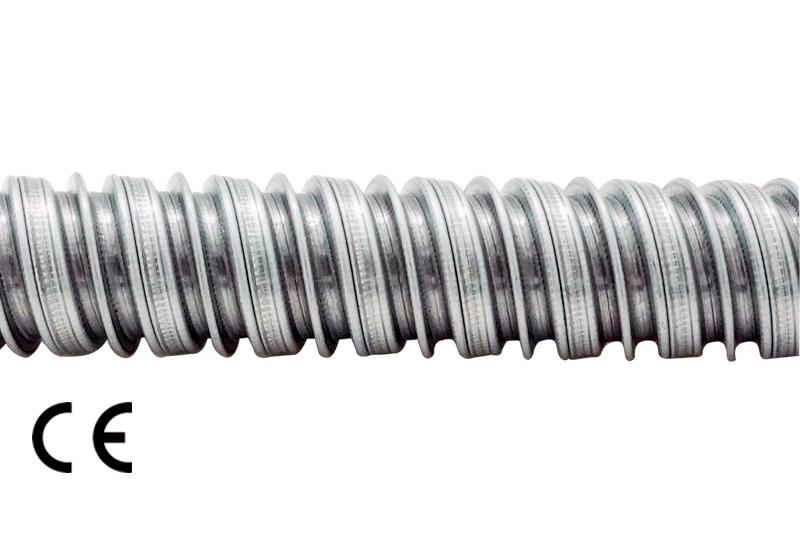

Flexible Metal Conduit also known as FMC, is a type of electrical conduit that provides protection for wiring in areas where flexibility is required. It is commonly used in commercial and industrial applications where rigid conduit is impractical. Flexible Metal Tubing is made of a spiral-wound metal strip with an outer PVC coating, making it flexible yet durable.

Tools and Materials Needed

Before you begin the installation process, ensure you have the following tools and materials:

Flexible Metal Conduit (FMC)

FMC connectors

Fish tape

Conduit bender

Screwdriver

Wire cutter/stripper

Electrical tape

Related links:Ultimate Guide to Motor Housing: Everything You Need

Revolutionizing the Automotive Industry with Grey Iron Casting: Will Traditional Materials Soon Be Obsolete?

Top Tips for Pump Body Casting: HEBEI YOGEM Insights

How can heat treatment enhance grey cast iron casting durability and strength?

SHALE SHAKER USER'S GUIDE -drillingfluid.org

What are the maintenance tips for triplex mud pumps?

How Does Bespoke Copper Alloy Casting for Australia Work?

Safety gloves and goggles

Step-by-Step Installation Process

1. Planning and Preparation

Begin by planning the route for the FMC, considering factors such as obstructions, bends, and access points. Measure and cut the FMC to the required lengths using a conduit cutter or hacksaw. Ensure that the ends are smooth and free from burrs.

2. Mounting the FMC

Secure the FMC in place using appropriate mounting hardware, such as straps or clamps. Ensure that the conduit is adequately supported and spaced according to local building codes.

3. Making Connections

Install FMC connectors at both ends of the conduit, ensuring a secure and watertight connection. Use a screwdriver to tighten the connectors securely.

4. Pulling Wires

Use a fish tape to pull the wires through the FMC. Ensure that the wires are properly sized and rated for the electrical load. Avoid overfilling the conduit, as this can lead to overheating and damage.

5. Bending the Conduit (if necessary)

If the Metallic Fittings needs to bend to navigate corners or obstacles, use a conduit bender to achieve smooth, gradual bends without kinking or damaging the conduit.

6. Securing Connections

Once the wires are in place, secure the connections using appropriate fasteners, such as locknuts or bushings. Inspect the connections for any signs of damage or looseness.

7. Testing and Inspection

Before powering up the electrical system, conduct a thorough inspection of the FMC installation. Check for proper grounding, secure connections, and adherence to local electrical codes.

By following these steps and safety precautions, you can ensure a successful and code-compliant installation of flexible metal conduit for your electrical wiring projects.

4 Advice to Choose a Valve Casting |HEBEI YOGEM

How do I select an investment casting pump body?

Top Automotive OEM Companies

Lead screw nut

Pump Up Your Oil Drilling Performance: Gears!

High Head Slurry Pump: A Reliable Solution for Efficient Handling of Abrasive Slurries

Drum Gear Coupling: The Versatile Link in Power Transmission Systems

144

0

0

Related Articles

-

362

0

0

-

313

0

0

-

391

0

0

-

329

0

0

-

337

0

0

-

315

0

0

-

315

0

0

-

334

0

0

Comments

All Comments (0)