All about Double Cone Blender

May. 06, 2024

All about Double Cone Blender

The Double Cone Blender is a versatile piece of machinery for mixing dry powders and any type of granule in a homogenous manner. The slant design of this double cone blender eliminates any dead spots that sometimes occur in the traditional and conventional double cone mixer. There is a conical shape that enables a very uniform mixing and a very easy discharge. They can handle large capacities and are easy to clean, load, and unload.

If you are looking for more details, kindly visit double cone mixer working principle.

Working principle of Double Cone BlenderDouble cone blender comes in a standard and compact design. All the powder and granules are loaded into the cone for the mixing process to start. Only two-thirds of the cone is filled to ensure complete mixing. The cone of the double cone blender is placed statistically so the chances of overload on the mixture are eliminated. The paddle type baffle in the cone strategizes the uniform mixing in the cone. The stipulated time is taken to mix which may vary depending on how difficult the substance to be mixed may be. The side-valve then helps in the discharge of the mixed material. The double cone blender has a polished surface which makes it very easy to be cleaned manually.

Advantages of the Double Cone Blender

This adaptable and versatile machine is a very effective machine for mixing dry powder, granules, or any heavy and abrasive material. What facilitates quick functionality is the timer function. This function makes it more precise. The shape of the cone and the multi shearing plate aid in blending and also easy residual removing. The machines carry the option of adding more paddle-shaped baffles for better blending. The Double cone blenders are supplied with Intensifier bars to allow for de-agglomeration if required. This enables any loosely adhered clumps of powder to be broken apart, thereby maintaining consistency. There is a fire motor attached which prevents the risk of any accidents. When it comes to output delivery, the double cone blender delivers high uniformity in blending especially when the mixing units vary in bulk density. The stainless steel body and its strong nature ensure durability and less wear and tear.

The double cone blender is used in laboratory, which is known as lab double cone blenders or R&D Double Cone Blender. Due to its small and compact size, they are also known as small double cone blender or mini double cone blender.

The laboratory double cone blender provides clients a high level of satisfaction and can be ordered with the required specifications. What makes this premium quality double cone blender high in demand is its robust design, long service life because of its endurability, and uninterrupted high performance. The lab double cone blenders offer fully integrated motors and controls and safety railings. Another feature of this blender is that it can be easily connected and disconnected with a quick locking and unlocking screw.

The R &D Double Cone Blender provides the latest technology benefits for powder and liquids with an efficient and cost-saving mechanism. The exceptional efficiency of this blender is due to its three-dimensional motion for constant and reproducible mixing results. The substances to be blended are subject to a rhythmic pulsing motion.

Contact us to discuss your requirements of mushroom grinder machine. Our experienced sales team can help you identify the options that best suit your needs.

Related links:High RPM Spindles: 5 Advantages for 5-axis CNC Machines

How do you package powder products?

How to Build a 3D Welding Table

What are the advantages of using Gang Type CNC Lathe?

The Inner Workings of a Production Freeze Dryer

Harnessing the Power of Ozone Generators: A Deep Dive into Applications and Benefits

Is it worth buying a new gas boiler?

Small compact double cone blenders or mini double cone blenders which occupy less space and carry out operations with minimum human interventions. These are of much use where batch sizes are smaller. These can be used for pharmaceutical, food, chemical, and cosmetic products. The High-speed double cone blenders can be utilized where the batches are larger and up-scaling or production is required.

Features and working principle of double cone mixer

Features and working principle of double cone mixer

The double cone mixer is mainly used for the uniform mixing of powder and granular materials in the pharmaceutical, препаратвлӓштӹ, electronic, and food industries.

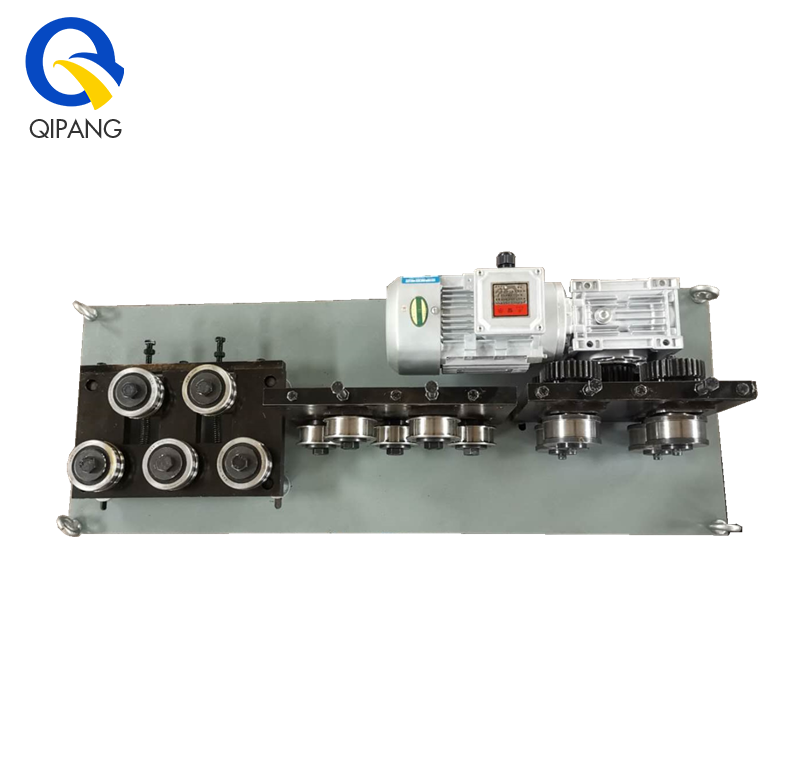

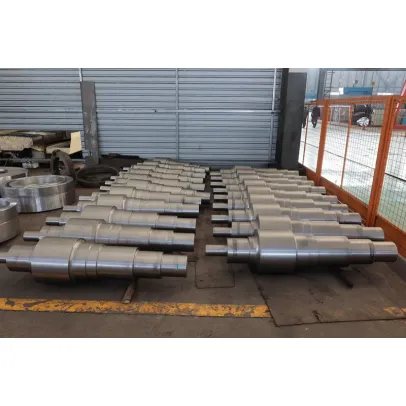

The double cone mixer is mainly composed of a mixing barrel, a frame, a transmission system, an electrical system, странице. It uses two asymmetric barrels and adopts gravity mixing. The materials are continuously gathered and dispersed in the barrel, generally passing through It takes about 10-30 minutes to mix, so that two or more powder and granular materials are fully mixed evenly. It is suitable for mixing two or more materials with a large disparity in specific gravity. The mixer is equipped with a set of stirring shafts in the mixing machine. During the process, the agglomeration shaft has the function of breaking, and the mixing uniformity is more than 99%.The inner and outer walls of the mixing barrel are precisely polished, and the surface is smooth and flat.During the working process of the transmission system, there is no jitter, no noise, convenient maintenance, sensitive electrical control, stainless steel butterfly valve discharge, no leakage, no dust.The double cone mixer has a beautiful appearance and a wide range of uses. It is an ideal equipment for mixing materials.

The double cone mixer transfers powder or granular materials into the double-cone container by vacuum conveying or manual feeding. As the capacity is broken, the material undergoes complex impact movement in the container to achieve uniform mixing.

Our main product are Sieving machine,Vibro sifter machine,Ultrasonic sieving machine,Вакуумный конвейер,Dumping station,Tumbler screening machine, Industrial sieving machine, Фильтрвлӓ вишкӹдӹ, Rectangular gyratory sifter, Screw conveyor and etc.

Please feel free to contact us if you need any support.

Sales Dep: Sales@vibrosievingmachine.com, Cell/WhatsApp:+86 13162301696

Want more information on function of Cinnamon Pulverizer? Feel free to contact us.

What is the temperature of a vibrating screen bearing?

Everything You Need to Know About Pipeline Welding

How does the 3D foam cutting machine work?

How does spark plasma sintering work?

What are the advantages of using DC TIG welding machine?

What is a slip ring motor used for?

What is PCB Labeling Machine

142

0

0

Related Articles

-

259

0

0

-

305

0

0

-

374

0

0

-

253

0

0

-

282

0

0

-

426

0

0

-

380

0

0

-

250

0

0

Comments

All Comments (0)